Quality tapes for packaging

When considering which tape to use for your packaging needs, several factors should be taken into account, such as the required level of security, the intended use of the package, and the application method. Multifoil is a specialty manufacturer of self-adhesive tapes for the paper and packaging industry, offering solutions for both manual and mechanical bonding.

Certain high-value items, including electronics, automotive spare parts, and prescription medications, are often targeted by criminals because of their potential resale value on the black market. In these cases, standard packaging tape may not provide sufficient protection. This is where Multifoil's expertise as a manufacturer of high-end, ultra-destructible self-adhesive tapes comes into play. Our specialized tapes are specifically engineered to meet the needs of this market, providing optimal security and peace of mind.

Box sealing tape

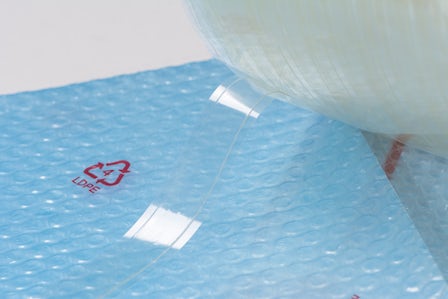

Bubble bag sealing tape

Tamper evident tapes for the pharmacy

The EU has several laws and regulations related to the distribution of medicinal products. One of the main pieces of legislation aims to prevent the entry of falsified medicines into the legal supply chain. Secure packaging is mandatory in Europe. We developed different options for the pharmacy market in order to meet the mandatory goals of the EU. For more information:https://www.ema.europa.eu/en/news/new-safety-features-medicines-sold-eu

Tamper evident packaging spare parts

Spools and bobbins

Custom solutions

Often we get a call for box sealing tape, a packaging tape. As a Dutch manufacturer, we are not able to compete with these types of tapes. What we can do, and do well, is manufacturing packaging tapes that need a bit extra! So how do you know if your application is better off with more quality?

Here are some key considerations to help you make an informed decision:

- Application: Determine the specific purpose for which you need packaging tape. Are you sealing boxes for shipping, packaging products for storage, or bundling items together? Different applications may require different types of tape.

- Weight and size of the package: Consider the weight and size of the packages you will be sealing. Heavier or larger packages may require stronger and wither tape to ensure secure sealing and prevent package failure during transit.

- Adhesive type: Packaging tapes come with different adhesive formulations, such as acrylic, hot melt, or natural rubber. Each type offers different characteristics in terms of adhesion strength, temperature resistance, and application surface compatibility. Consider the conditions in which the package will be handled and transported to select an adhesive that suits your needs.

- Tape strength: Some packaging tapes are reinforced with materials like fiberglass or polyester to provide extra strength and durability. If you are shipping heavy items or need added security, consider tapes with reinforced strength for optimal performance.

- Surface compatibility: Consider the surfaces you will be applying the tape to. Different tapes may adhere better to specific surfaces, such as cardboard, plastic, or metal. Ensure that the tape you choose is compatible with the surface materials to achieve strong adhesion.

- Environmental factors: If your packages will be exposed to extreme temperatures, humidity, or UV radiation, look for tapes that offer resistance to these environmental conditions. Certain tapes are designed to withstand harsh environments and maintain their adhesion properties.

- Dispensing method: Consider the type of tape dispenser or applicator you will be using. Some tapes are specifically designed for manual application, while others are optimized for use with tape dispensers. Ensure compatibility between the tape and your preferred dispensing method.

- Budget: Evaluate your budget and consider the cost-effectiveness of the tape. While it’s important to select a tape that meets your requirements, be mindful of cost considerations as well.

By considering these factors, you can narrow down the options and choose a packaging tape that best fits your specific needs. If in doubt, consult with our experts!

Determining the quality of packaging tape involves assessing several key factors. Here are some indicators to help you determine if the tape you’re using is of high quality:

- Adhesive strength: High-quality packaging tape should have a strong adhesive that provides excellent bonding to various surfaces. It should adhere securely and maintain its adhesion over time, even in different environmental conditions.

- Durability: The tape should be resistant to tearing, splitting, or stretching when applied and during handling or transportation. It should maintain its integrity and not easily break or fray.

- Thickness and tensile strength: Check the thickness and tensile strength specifications of the tape. Thicker tapes generally offer higher strength and durability, providing better resistance to punctures or damage.

- Compatibility with surfaces: The tape should adhere well to a variety of surfaces commonly used for packaging, such as cardboard, plastic, or metal. It should not easily peel off or lose adhesion when applied to these surfaces.

- Temperature resistance: Consider the temperature range the tape can withstand. High-quality tapes are designed to maintain their adhesive properties and structural integrity even in extreme temperatures, whether hot or cold.

- Moisture resistance: Packaging tapes may need to withstand moisture or humidity during storage or transportation. Look for tapes that are specifically designed to resist moisture and maintain their adhesive strength in such conditions.

- Certifications and standards: Check if the packaging tape meets industry standards or certifications for quality and performance, such as those provided by recognized organizations or regulatory bodies.

By assessing these factors, you can make a more informed judgment about the quality of the packaging tape you’re using. It’s always recommended to do intensive testing before deciding.

More information

Any special demands, projects, or challenging applications in the packaging industry? Contact us, it’s what we do best.

Our promise

We have the advantage of possessing an in-house laboratory, a proficient R&D team, and 4 decades of production know-how. This enables us to engineer and produce the most optimal long-term results for you.

At our company, we strive to provide excellence in all aspects of our operations, including the sourcing of high-quality raw materials, the manufacturing of top-notch products, rigorous development and testing processes, and outstanding service delivery to our valued customers. Rest assured that our commitment to quality is unwavering.

We understand that collaborating towards a solution and sharing your knowledge, developments and market insight can be a daunting task. However, please be assured that we value integrity and trust above all else in our work with you. Any confidential information you share with us will be kept strictly confidential and if needed we will be happy to sign an NDA. Let's work together towards finding the best solutions for your needs.

Long-term relationships can seem almost inevitable when bonding is the foundation of your company. We are fortunate that many of our valued customers, both large and small, choose to stay with us for extended periods, often until the end of their application. Equally important to us are our suppliers, to whom we remain loyal, just as our customers remain loyal to us. And finally, our team - once you become part of our ‘sticky’ group, it's challenging to break away.

We take pride in our production facility, equipped with over 20 high-performing converting machines and 5 coating lines for rubber and acrylic. Our team is equally impressive, boasting an average tenure of 14 years, and they are more than capable of tackling any challenge thrown their way. Our shared passion for excellence makes working together a joy, and you will undoubtedly feel this sense of enthusiasm and commitment when collaborating with us.

With our expansive warehouse stocked with finished products and raw materials, we guarantee on-time delivery that precisely matches your specifications. In addition, we can fulfill call-off orders, granting you access to your products exactly when you need them. Our delivery and service team has years of international experience and is eager to assist you in any way they can.