Double-sided tapes for the automotive industry

As a manufacturer operating within the automotive industry, we actively contribute to various sectors such as automotive, carrosserie build, and bodywork where tapes play a crucial role. Our expertise lies in the production of custom-made self-adhesive solutions usually exclusively designed for a specific application. Contact us for your specific bonding requests.

Carrosserie & Car body assembly

Tamper packaging spare parts

Tailored adhesive and coating

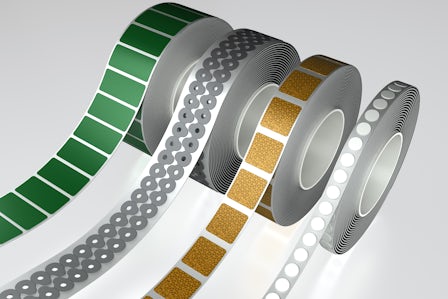

As we do in-house coating we are able to engineer a tape with a specific pattern and combine this pattern with the best-suited adhesive for your automotive application. For more on our coating capabilities go to:www.multifoil.com/whatwedo/coating

Tailored die-cuts

Foam tapes for the automotive

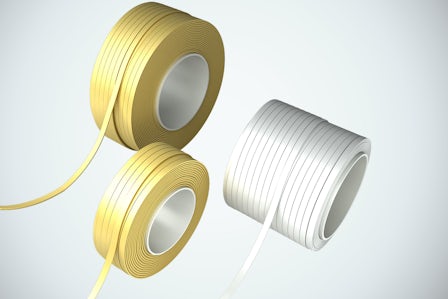

Double side foam tapes

Yes, tape can be an effective alternative to traditional mechanical fasteners in certain automotive applications. While mechanical fasteners like screws, bolts, and rivets have been traditionally used for joining and securing automotive components, tape offers several advantages that make it a viable alternative:

- Weight reduction: Tape is typically lighter than mechanical fasteners, making it advantageous in industries where weight reduction is a priority, such as the automotive industry. This can contribute to improved fuel efficiency and overall vehicle performance.

- Enhanced aesthetics: Tape can provide a cleaner and more streamlined appearance compared to visible mechanical fasteners. It allows for smooth surfaces without the need for drilled holes or protruding fastener heads, which can improve the vehicle's overall design and aesthetics.

- Vibration damping and noise reduction: Tape has the ability to absorb and dampen vibrations, reducing noise and enhancing the overall comfort of the vehicle. This can be particularly useful in areas where vibration and noise need to be minimized, such as attaching interior trims or insulating panels.

- Sealant properties: Certain tapes are designed to provide sealing capabilities, effectively preventing the ingress of water, dust, or other contaminants. This can be beneficial in automotive applications where maintaining a watertight or dustproof seal is important, such as in weatherstripping or sealing electrical connections.

- Improved manufacturing efficiency: Tape can simplify the assembly process by reducing the number of required components and the associated labor. It can be applied quickly and easily, reducing assembly time and improving manufacturing efficiency.

However, it's important to note that tape may not be suitable for all automotive applications. Factors such as load-bearing requirements, extreme temperatures, chemical exposure, and long-term durability need to be carefully considered when Determining whether tape is a suitable alternative to mechanical fasteners in a specific automotive application.

When selecting tape for specific automotive applications, several factors should be considered to ensure optimal performance and suitability. Here are some key factors to consider:

- Bonding Surface: Understand the characteristics of the surfaces that need to be bonded. Consider factors such as the material (plastic, metal, glass, etc.), surface texture, cleanliness, and any surface treatments or coatings present. Different tapes may be better suited for bonding to specific surface types.

- Application Environment: Assess the environmental conditions the tape will be exposed to, including temperature variations, humidity, UV exposure, chemicals, oils, and vibrations. Choose a tape that can withstand specific environmental conditions without losing its adhesive strength or physical properties.

- Load Requirements: Determine the load-bearing requirements of the application. Consider factors such as the weight of the components being joined, the forces acting upon them (vibration, impact, etc.), and the expected service life. Select a tape with sufficient strength and durability to handle the anticipated loads.

- Compatibility: Ensure compatibility between the tape and other materials or substrates it will come into contact with. Consider any potential chemical reactions or incompatibilities that may affect the tape's performance or the integrity of the bonded surfaces.

- Application Method: Consider the application process and equipment available. Some tapes require specific application techniques, such as heat activation or pressure-sensitive application. Ensure that the chosen tape can be easily applied using the available resources.

- Regulatory Compliance: In the automotive industry, it's essential to consider any relevant regulations or industry standards that apply to the specific application. Ensure that the selected tape meets the necessary requirements for safety, flame resistance, emissions, or other relevant standards.

- Longevity and Service Life: Evaluate the expected lifespan of the application and choose a tape that can provide the required durability and longevity. Consider factors such as aging resistance, resistance to environmental factors, and long-term adhesion properties.

- Aesthetics: Depending on the application, aesthetics may be a consideration. Determine if the tape needs to be visible or hidden, and select a tape that meets the desired visual requirements, such as color, transparency, or texture.

- Testing and Validation: We value thorough application testing and validation of the suggested tape in the specific application conditions before full-scale implementation. This can help ensure that the tape performs as expected and meets the necessary performance requirements.

Tamper packaging is important in the supply chain of spare parts for the automotive industry for several reasons:

- Product Integrity: Tamper packaging helps ensure the integrity of spare parts throughout the supply chain. It provides a physical barrier that protects the parts from unauthorized access, tampering, or contamination. This is crucial for maintaining the quality and functionality of automotive spare parts, as any tampering or contamination can compromise their performance and safety.

- Counterfeit Prevention: The automotive industry is susceptible to counterfeit spare parts, which can pose serious safety risks and cause significant damage to vehicles. Tamper packaging includes features such as holograms, seals, or unique identifiers that can help verify the authenticity of the parts. By incorporating these anti-counterfeiting measures, tamper packaging helps prevent the distribution of counterfeit parts, ensuring that only genuine, reliable products reach the end customers.

- Traceability and Chain of Custody: Tamper packaging can include tracking mechanisms such as barcodes, RFID tags, or serial numbers. These features enable efficient tracking and monitoring of spare parts throughout the supply chain. By maintaining a clear chain of custody, tamper packaging helps c the origin, location, and movement of parts, which is essential for quality control, warranty claims, and product recalls if necessary.

- Regulatory Compliance: The automotive industry is subject to various regulations and standards regarding product safety, quality, and traceability. Tamper packaging can help companies comply with these regulations by providing s of product integrity and adherence to required procedures. It demonstrates a commitment to quality control and ensures that the spare parts meet the necessary standards.

- Customer Confidence: Tamper packaging plays a crucial role in building customer confidence and trust. By visibly demonstrating that a company takes the security and quality of its spare parts seriously, it reassures customers that they are purchasing genuine and reliable products. This can enhance brand reputation, customer satisfaction, and loyalty.

The use of suitable double-sided tape can make the difference when closing your bubble bag, PE, or cardboard box in ensuring its valuable content.

More information

Tapes are commonly used in cars, trucks, caravans, and campervans. We recognize the challenges of discovering the right tape, as it often involves extensive effort. Let us do the work!

Our promise

We have the advantage of possessing an in-house laboratory, a proficient R&D team, and 4 decades of production know-how. This enables us to engineer and produce the most optimal long-term results for you.

At our company, we strive to provide excellence in all aspects of our operations, including the sourcing of high-quality raw materials, the manufacturing of top-notch products, rigorous development and testing processes, and outstanding service delivery to our valued customers. Rest assured that our commitment to quality is unwavering.

We understand that collaborating towards a solution and sharing your knowledge, developments and market insight can be a daunting task. However, please be assured that we value integrity and trust above all else in our work with you. Any confidential information you share with us will be kept strictly confidential and if needed we will be happy to sign an NDA. Let's work together towards finding the best solutions for your needs.

Long-term relationships can seem almost inevitable when bonding is the foundation of your company. We are fortunate that many of our valued customers, both large and small, choose to stay with us for extended periods, often until the end of their application. Equally important to us are our suppliers, to whom we remain loyal, just as our customers remain loyal to us. And finally, our team - once you become part of our ‘sticky’ group, it's challenging to break away.

We take pride in our production facility, equipped with over 20 high-performing converting machines and 5 coating lines for rubber and acrylic. Our team is equally impressive, boasting an average tenure of 14 years, and they are more than capable of tackling any challenge thrown their way. Our shared passion for excellence makes working together a joy, and you will undoubtedly feel this sense of enthusiasm and commitment when collaborating with us.

With our expansive warehouse stocked with finished products and raw materials, we guarantee on-time delivery that precisely matches your specifications. In addition, we can fulfill call-off orders, granting you access to your products exactly when you need them. Our delivery and service team has years of international experience and is eager to assist you in any way they can.